Understanding how to calculate alcohol by volume is essential for anyone serious about brewing beer, making wine, or distilling spirits. Whether you’re a weekend homebrewer tracking your latest IPA or a commercial producer ensuring regulatory compliance, an accurate alcohol by volume abv calculator becomes your most trusted tool.

In this comprehensive guide, you’ll learn everything you need to know about ABV calculations, from basic formulas to advanced measurement techniques. We’ll walk through practical examples, troubleshoot common errors, and help you choose the right tools for precise alcohol content measurement. By the end, you’ll confidently measure the strength of any alcoholic beverage you create.

What is ABV and How to Calculate It

Alcohol by volume represents the percentage of pure ethanol present in 100 milliliters of liquid at a standard temperature of 20°C (68°F). When fermentation begins, yeast converts sugars into alcohol and carbon dioxide, changing the density of your beverage. This density change forms the basis for most ABV calculations.

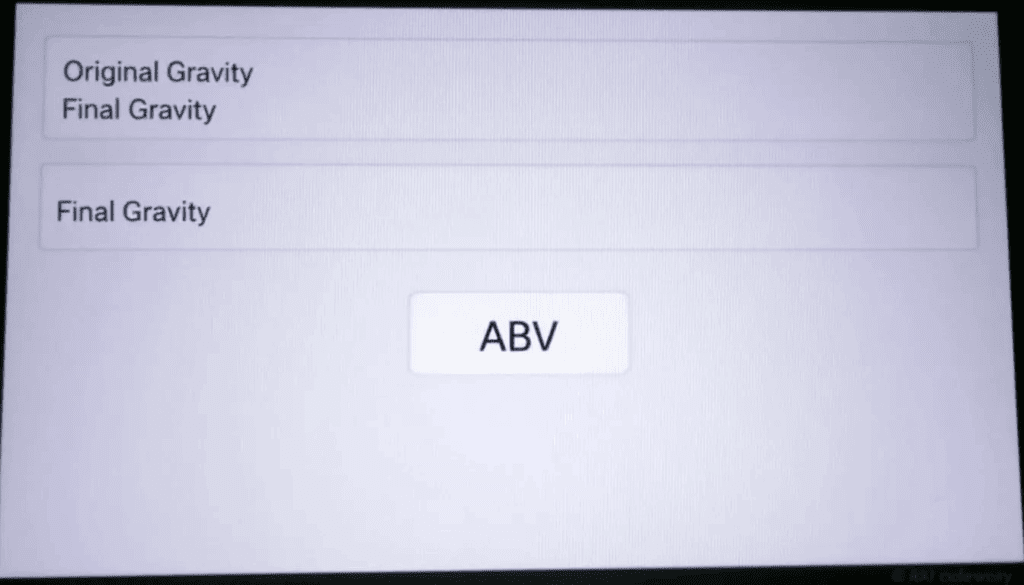

The most widely used formula for calculating ABV in homebrewing is:

ABV = (Original Gravity – Final Gravity) × 131.25

This equation works because alcohol has a lower density than water. As yeast consumes sugar and produces alcohol, the specific gravity of your liquid decreases proportionally to the amount of alcohol created.

Alternative calculation methods use Plato degrees, which measure sugar concentration directly. Professional breweries often prefer Plato-based calculations for their precision, especially when dealing with high-gravity beverages. However, the standard gravity-based formula remains the most accessible for home brewers.

Understanding ABV matters for several critical reasons. Consumers need accurate information about alcohol content for responsible consumption. Brewers use ABV to ensure consistency between batches and meet style guidelines. Regulatory authorities require precise labeling for taxation and legal compliance.

Using an ABV Calculator for Homebrewing

Proper ABV calculation starts with accurate gravity measurements. Before fermentation begins, you’ll measure the original gravity using a calibrated hydrometer. This reading captures the total amount of fermentable sugars available to yeast.

First, calibrate your hydrometer by placing it in distilled water at room temperature. It should read exactly 1.000. If not, note the difference and adjust all future readings accordingly. Temperature affects density, so ensure your samples match your hydrometer’s calibration temperature.

To measure original gravity, draw a sample of your wort into a test jar. Gently lower the hydrometer, avoiding air bubbles that could affect buoyancy. Read where the liquid surface intersects the scale. A typical beer might show an OG of 1.055, indicating the liquid is 5.5% denser than water due to dissolved sugars.

After fermentation completes, typically 7-14 days depending on your recipe, take a final gravity reading using the same process. The final gravity for our example beer might read 1.012. Using our formula: (1.055 – 1.012) × 131.25 = 5.64% ABV.

Several factors can affect reading accuracy. CO₂ bubbles from active fermentation will make your hydrometer float higher, giving false readings. Always ensure fermentation has completely finished before taking final measurements. Temperature variations can also skew results, so let samples reach room temperature before measuring.

Understanding Specific Gravity in ABV Calculations

Specific gravity compares the density of your liquid to pure water, which serves as the baseline with a value of 1.000. This measurement system allows precise tracking of sugar content and alcohol formation throughout the brewing process.

During fermentation, yeast converts sugar molecules into ethanol and carbon dioxide. Since ethanol is less dense than both water and sugar, the specific gravity drops as alcohol replaces sugar. This density change creates a reliable method for determining alcohol content without complex chemical analysis.

The relationship between gravity drop and alcohol formation follows predictable patterns. Each 0.001 decrease in specific gravity typically indicates about 0.125% ABV increase, though this varies slightly based on the specific sugars involved and fermentation conditions.

Monitoring specific gravity also helps track fermentation progress. Active fermentation shows steadily declining readings, while stable readings over several days indicate completion. This information helps you determine when to proceed with bottling or secondary fermentation steps.

Original vs Final Gravity Measurements

Original gravity indicates the total fermentable material available before yeast activity begins. Light beers typically show OG readings between 1.035-1.045, while stronger imperial styles may reach 1.070-1.100 or higher. These numbers help predict the final alcohol content and guide recipe formulation.

Final gravity represents the remaining unfermented material after yeast completes its work. Dry beers finish between 1.005-1.012, creating crisp, clean flavors with higher alcohol content. Sweet beers maintain higher final gravity readings of 1.015-1.025, preserving residual sugars for body and sweetness.

The difference between original and final gravity determines both alcohol content and apparent attenuation. Higher attenuation percentages indicate more complete sugar conversion, resulting in drier beverages with higher alcohol content. Lower attenuation leaves more residual sweetness but reduces final ABV.

Understanding these ranges helps evaluate fermentation success and troubleshoot problems. Stuck fermentation shows higher-than-expected final gravity, while infected batches may show unusually low readings due to wild yeast or bacteria consuming sugars the primary yeast cannot process.

ABV Calculator for Different Beverages

Different alcoholic beverages require adjusted calculation approaches due to varying sugar sources and fermentation patterns. Beer calculations using standard gravity-based formulas work well for most grain-based beverages, but wine and spirits present unique challenges.

Wine ABV determination must account for much higher initial sugar content. Grape juice typically starts with gravity readings of 1.080-1.100, potentially reaching 12-15% ABV. The standard formula works, but wine fermentation often drives final gravity below 1.000 as yeast consumes virtually all available sugars.

Cider and mead calculations require consideration of fruit sugar characteristics. Apple juice contains different sugar types than malted grain, affecting fermentation patterns and final alcohol yields. Honey in mead ferments differently than both fruit and grain sugars, sometimes requiring extended fermentation periods.

Spirit ABV measurement for distilled beverages uses different principles entirely. Distillation concentrates alcohol beyond what fermentation alone can achieve, requiring direct alcohol measurement rather than calculation from gravity changes. Professional distillers use specialized equipment like alcohol hydrometers or electronic meters.

Commercial beverage calculators have limitations compared to homemade versions. Mass-produced drinks often contain additives, stabilizers, or artificial ingredients that affect density without contributing to alcohol content. These factors can make reverse-engineering ABV from gravity measurements unreliable.

Advanced ABV Calculation Methods

The Cutaia, Reid, and Speers formula, published in the Journal of Institute of Brewing, provides enhanced accuracy for professional applications. This method accounts for complex interactions between alcohol, water, and extract that the simplified homebrewing formula doesn’t address.

Real versus apparent attenuation affects ABV accuracy significantly. Apparent attenuation measures the percentage decrease in extract based on gravity readings, but alcohol’s lower density makes this measurement appear higher than actual sugar consumption. Real attenuation requires laboratory analysis to determine true sugar conversion rates.

Temperature correction factors ensure precise gravity readings regardless of sample temperature. Most hydrometers calibrate to 60°F (15.6°C) or 68°F (20°C). Samples at different temperatures need mathematical correction, typically adding 0.001 gravity points per 10°F above calibration temperature.

Alcohol density considerations become critical at higher concentrations. Pure ethanol has a specific gravity of 0.789, significantly lower than water. As alcohol percentage increases, the linear relationship between gravity change and ABV becomes less accurate, requiring more sophisticated calculation methods.

Apparent Attenuation and Its Impact

Apparent attenuation represents the percentage of original extract consumed during fermentation, calculated as: (OG – FG) / (OG – 1.000) × 100. This measurement helps evaluate yeast performance and fermentation completeness across different brewing conditions.

The term “apparent” acknowledges that alcohol’s lower density makes sugar consumption appear higher than reality. True attenuation requires complex laboratory procedures to separate alcohol effects from actual extract reduction, making apparent attenuation more practical for most applications.

Attenuation affects final beer body, flavor, and alcohol content significantly. High attenuation (75-85%) creates dry, crisp beers with prominent alcohol character. Lower attenuation (65-75%) preserves sweetness and body while reducing alcohol strength.

Typical attenuation ranges vary by yeast strain and beer style. Lager yeasts often achieve 75-85% apparent attenuation, while ale yeasts range from 65-80%. Understanding these patterns helps brewers select appropriate yeasts and predict final beverage characteristics.

ABV vs Other Alcohol Measurements

ABV (Alcohol By Volume) differs from ABW (Alcohol By Weight) due to alcohol’s lower density compared to water. Since ethanol weighs about 79% as much as water, ABW readings are roughly 20% lower than equivalent ABV measurements. Most consumer labeling uses ABV for consistency.

The proof system creates another measurement standard, primarily used in the United States. US proof equals exactly twice the ABV percentage, so 80 proof spirits contain 40% ABV. This system originated from historical testing methods using gunpowder ignition to verify alcohol content.

International variations include Gay-Lussac degrees, still used in France and some European countries. This scale measures alcohol percentage at 15°C instead of 20°C, creating slight differences from standard ABV measurements. The temperature difference typically affects readings by less than 0.1%.

Conversion examples help clarify these relationships: 80 proof equals 40% ABV, 100 proof equals 50% ABV, and 151 proof equals 75.5% ABV. Wine at 12% ABV would measure approximately 9.6% ABW and 24 proof, though proof is rarely used for wine labeling.

Practical ABV Calculator Examples

Light beer provides an excellent starting example for ABV calculations. With an original gravity of 1.040 and final gravity of 1.008, the calculation becomes: (1.040 – 1.008) × 131.25 = 4.2% ABV. This result fits typical light beer strength expectations.

An IPA calculation demonstrates higher alcohol content brewing. Starting with OG 1.065 and finishing at FG 1.014: (1.065 – 1.014) × 131.25 = 6.7% ABV. The higher original gravity from additional malt creates the stronger final product.

Imperial stout represents extreme brewing calculations. With OG 1.090 and FG 1.018: (1.090 – 1.018) × 131.25 = 9.4% ABV. These high-gravity beers require careful yeast management and extended fermentation to achieve proper attenuation.

Wine examples show different fermentation patterns. Starting with OG 1.095 and finishing below water at FG 0.995: (1.095 – 0.995) × 131.25 = 13.1% ABV. The sub-1.000 final gravity indicates nearly complete sugar consumption.

Volume calculations help determine actual alcohol content per serving. A 12-ounce bottle at 5% ABV contains 0.6 ounces of pure alcohol (12 × 0.05 = 0.6). Understanding these numbers supports responsible consumption and accurate recipe scaling.

Common ABV Calculator Errors and Solutions

Incorrect hydrometer calibration causes systematic errors in all gravity readings. Always test your hydrometer in distilled water before use. If readings don’t show exactly 1.000, either replace the instrument or consistently apply the correction factor to all measurements.

Temperature effects create significant measurement errors if ignored. Hot samples read lower than actual gravity, while cold samples read higher. Let all samples reach your hydrometer’s calibration temperature, typically room temperature, before taking readings for accurate results.

Taking readings before fermentation completes leads to artificially high final gravity measurements. Ensure fermentation has been stable for at least 2-3 days before calculating final ABV. Active fermentation continues to drop gravity readings, affecting calculation accuracy.

Priming sugar additions before bottling affect final ABV calculations. The small amount of sugar added for carbonation will ferment in the bottle, slightly increasing alcohol content. Factor this addition into your calculations or measure gravity before priming for consistency.

Damaged or poorly calibrated hydrometers produce unreliable readings throughout their working life. Inspect your hydrometer regularly for cracks, chips, or scale damage. Replace instruments showing any physical damage or calibration drift for accurate measurements.

ABV Calculator Tools and Resources

Online ABV calculators offer convenient alternatives to manual calculations, with most providing instant results from gravity inputs. Popular brewing websites host reliable calculators that include temperature correction and multiple unit options for international users.

Mobile brewing apps integrate ABV calculation with comprehensive brewing management features. These tools often store batch histories, track multiple fermentations simultaneously, and provide additional brewing calculations beyond simple ABV determination.

Digital refractometers provide quick gravity measurements using small sample volumes. While more expensive than traditional hydrometers, they offer convenience for frequent testing and work well for monitoring fermentation progress without removing large samples.

Hydrometer versus refractometer accuracy depends on proper calibration and use. Hydrometers excel for final gravity readings, while refractometers work better for original gravity measurement. Both require temperature correction and proper maintenance for reliable results.

Free calculator options provide basic ABV calculation functionality suitable for most homebrewing needs. Premium features in paid versions might include batch tracking, recipe scaling, and integration with brewing software systems for serious brewers managing multiple projects.

Important Note: These ABV calculators and measurement techniques are intended for educational and entertainment purposes. Professional brewing, distilling, and commercial production require certified equipment and may be subject to regulatory oversight. Always verify accuracy with appropriate testing methods for any commercial applications.

Understanding alcohol by volume calculation empowers you to create consistent, high-quality beverages while maintaining precise control over alcohol content. Whether you’re brewing your first batch of beer or refining advanced techniques, mastering these measurement skills ensures success in all your fermentation projects. Start with simple calculations, practice proper technique, and gradually explore more sophisticated methods as your brewing expertise develops.

Leave a Reply