Understanding fermentation is the difference between good beer and great beer. While many home brewers focus on recipe formulation and ingredient selection, the key to consistent, high-quality results lies in monitoring and controlling attenuation throughout the brewing process. A beer attenuation calculator provides the tools needed to predict, measure, and optimize how much sugar your yeast consumes during fermentation.

Whether you’re brewing your first batch or refining a flagship recipe, calculating attenuation can help you understand and manage the brewing process, offering support and guidance to achieve the exact flavor profile, alcohol content, and body you’re targeting. This comprehensive guide will show you how to use attenuation calculators effectively, understand gravity readings, and troubleshoot fermentation issues like a pro.

What is Beer Attenuation and How to Calculate It

Beer attenuation refers to the percentage of fermentable sugars converted by yeast during fermentation into alcohol, carbon dioxide, and other byproducts. This measurement directly impacts your beer’s sweetness, alcohol by volume (ABV), and overall character. Understanding attenuation is essential for predicting final gravity and achieving consistent brewing results.

There are two types of attenuation measurements you’ll encounter when using a beer attenuation calculator:

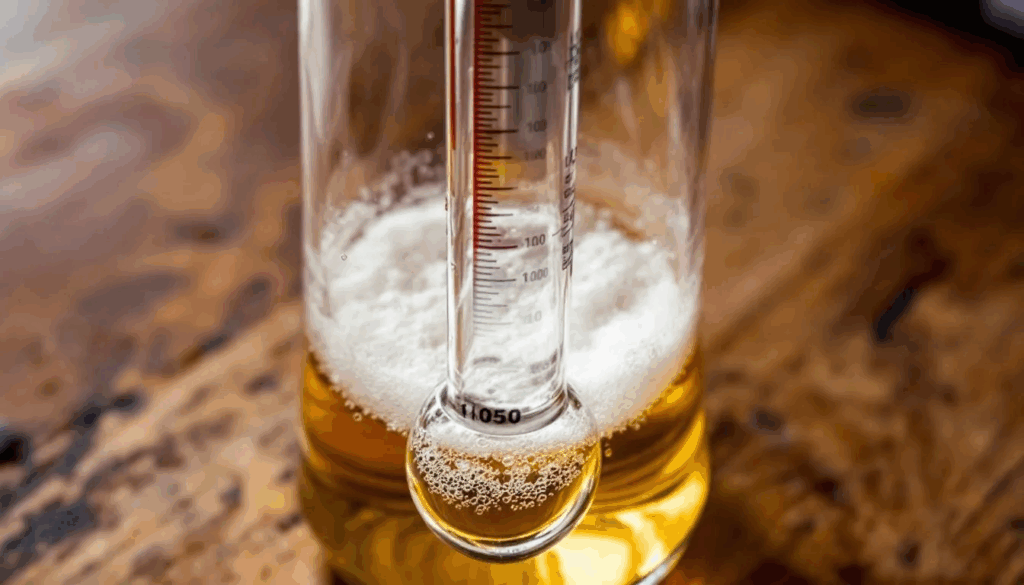

Apparent Attenuation (AA) is the standard measurement most home brewers use. It’s calculated based on original and final gravity readings taken with a hydrometer. Original gravity and specific gravity are used to determine both attenuation and the alcohol content of the beer. However, apparent attenuation overestimates actual sugar removal because alcohol has a lower density than water, making the final gravity appear lower than the true sugar content would suggest.

Real Attenuation (RA) provides a more accurate measure of actual sugar conversion by accounting for alcohol’s effect on density. Real attenuation typically measures about 15% lower than apparent attenuation and better reflects the beer’s perceived sweetness or dryness.

The formula for calculating apparent attenuation is:

Apparent Attenuation (%) = ((OG – FG) / (OG – 1)) × 100

Where OG is original gravity and FG is final gravity. For example, if your original gravity is 1.050 and final gravity is 1.010, your apparent attenuation would be ((1.050 – 1.010) / (1.050 – 1)) × 100 = 80%.

Why attenuation matters extends beyond simple measurement. Higher attenuation generally produces drier, more alcoholic beers with lighter body, while lower attenuation creates sweeter, fuller-bodied brews. Alcohol by volume (ABV) is used to express the percentage of alcohol in the finished beer, making it a key indicator of beverage strength. Most ales and lagers achieve apparent attenuation between 65-85%, though this range varies significantly based on yeast strain, fermentation conditions, and wort composition.

Using the Beer Attenuation Calculator

A beer attenuation calculator simplifies complex brewing calculations by automatically computing attenuation percentages, estimated alcohol content, and other key metrics from your gravity readings. Here’s how to use these tools effectively for consistent results.

Step 1: Enter Original Gravity Readings Take your original gravity reading before pitching yeast, ensuring your wort is at the calibration temperature (usually 60°F or 68°F depending on your hydrometer). Enter this value into the calculator as a decimal (1.050) or specific gravity points (50). Most calculators accept both formats and will convert automatically.

Step 2: Input Final Gravity Measurements Wait until fermentation appears complete before taking final gravity readings. This typically occurs when gravity remains stable for 2-3 consecutive days. Like original gravity, enter your final gravity reading in the format your calculator requires.

Step 3: Understanding Calculator Results Your beer attenuation calculator will display several key metrics:

- Apparent attenuation percentage

- Alcohol by volume (ABV)

- Calories per 12 oz serving

- Sometimes real attenuation estimates

Step 4: Timing Your Measurements For most accurate calculations, take original gravity readings after cooling but before yeast addition. Final gravity readings should only be taken when fermentation is truly complete – rushing this measurement leads to inaccurate attenuation calculations and potential issues if you bottle too early.

Advanced calculators may also estimate real attenuation using mathematical corrections, helping you better understand your beer’s actual sugar conversion and perceived dryness. Some calculators might include additional features or options depending on the user’s needs.

The beer attenuation calculator is provided for informational and educational purposes only, and results might not be exact.

Understanding Gravity Readings for Attenuation

Accurate gravity readings form the foundation of reliable attenuation calculations. Whether you’re using a traditional hydrometer or digital refractometer, proper measuring technique ensures your beer attenuation calculator provides meaningful results.

Using a Hydrometer for Specific Gravity A hydrometer measures liquid density by floating at different levels based on dissolved sugars. Fill a test jar with enough wort or beer to float the hydrometer freely, then read the measurement at eye level where the liquid surface meets the scale. Most hydrometers are calibrated for specific temperatures, typically 60°F or 68°F.

Taking Final Gravity Readings Final gravity measurements require patience. Fermentation may appear inactive while yeast continues working slowly. Take readings 24 hours apart – if gravity remains unchanged for three consecutive days, fermentation is likely complete. Rushing final gravity readings leads to inaccurate attenuation calculations and potential over-carbonation if bottling prematurely.

Temperature Corrections for Accuracy Temperature significantly affects gravity readings. Hot wort reads lower than actual gravity, while cold samples read higher. Most beer attenuation calculators include temperature correction features, but you can also use correction charts or formulas. For every 10°F above calibration temperature, add approximately 0.4 gravity points (0.004 specific gravity).

Common Gravity Ranges by Style Different beer styles have characteristic gravity ranges that affect expected attenuation:

Beer Style | Original Gravity | Final Gravity | Typical Attenuation |

|---|---|---|---|

Session Ales | 1.030-1.040 | 1.006-1.012 | 70-80% |

Standard Ales | 1.040-1.055 | 1.008-1.015 | 68-78% |

IPAs | 1.050-1.070 | 1.008-1.018 | 75-85% |

Stouts | 1.045-1.065 | 1.010-1.020 | 65-75% |

Lagers | 1.044-1.055 | 1.008-1.014 | 75-85% |

Typical Attenuation Ranges by Beer Style

Understanding expected attenuation ranges helps you evaluate fermentation performance and troubleshoot issues. Different beer styles naturally achieve different attenuation levels based on their grain bills, yeast strains, and fermentation parameters.

Ales vs. Lagers Saccharomyces cerevisiae (ale yeast) typically achieves 68-78% apparent attenuation, while Saccharomyces pastorianus (lager yeast) often reaches 75-85%. Lager yeasts generally attenuate more completely due to their ability to ferment a broader range of sugars at lower temperatures.

Yeast Strain Impact Individual yeast strains within the same species show significant attenuation differences:

- English ale yeasts: 65-72% (fuller body, more residual sweetness)

- American ale yeasts: 74-82% (cleaner, drier finish)

- Belgian strains: 78-85% (high attenuation, complex flavors)

- German lager yeasts: 80-85% (crisp, clean profile)

Grain Bill Composition Effects Your recipe’s grain bill directly influences potential attenuation. Base malts like Pilsner and Pale Ale malt provide highly fermentable sugars, while specialty grains add varying amounts of unfermentable dextrins. Crystal malts, in particular, contribute residual sweetness that lowers overall attenuation. Adjuncts like corn and rice increase fermentability, potentially raising attenuation above typical ranges.

Fermentation and Apparent Attenuation

Fermentation is at the heart of brewing, transforming sweet wort into flavorful beer by harnessing the power of yeast. During this process, yeast consumes the sugars present in the wort, converting them into alcohol by volume (ABV), carbon dioxide, and a range of flavor compounds that define your beer’s character. The efficiency of this transformation is measured by apparent attenuation—a key metric that tracks the reduction in specific gravity as fermentation progresses.

Apparent attenuation gives brewers a clear picture of how much sugar has been consumed by the yeast, expressed as a percentage. By monitoring this value, you can estimate how much of the wort’s sugars have been converted into alcohol and carbon dioxide, and predict the final alcohol content of your beer. This is where the ABV calculator becomes an essential brewing tool. By inputting your specific gravity readings before and after fermentation, the calculator uses apparent attenuation to provide an accurate estimate of your beer’s alcohol by volume.

Understanding and tracking apparent attenuation allows you to fine-tune your brewing process. If you notice that attenuation is lower or higher than expected, you can adjust factors like yeast selection, fermentation temperature, or wort composition to achieve your desired beer profile. Yeast plays a vital role here—its ability to efficiently convert sugars directly impacts both the alcohol content and the overall character of your finished beer.

Using an ABV calculator throughout fermentation helps you stay on top of your brewing, ensuring that you hit your target alcohol by volume and create a beer with the perfect balance of flavor, body, and strength. By mastering the relationship between fermentation, apparent attenuation, and ABV, you’ll be able to consistently produce high-quality beer tailored to your preferences.

Factors Affecting Beer Attenuation

Multiple variables influence how completely your yeast attenuates wort sugars. Understanding these factors helps you predict attenuation outcomes and adjust recipes or processes to achieve target results.

Yeast Strain Selection Yeast choice has the most significant impact on attenuation performance. High-attenuating strains like Safale US-05 or Lallemand Voss Kveik can reach 85% or higher, creating dry, crisp beers. Low-attenuating strains like London ESB or Munich lager yeasts may only reach 65-70%, leaving more residual sugars for body and sweetness.

Consider yeast specifications when planning recipes. If you want a malty, sweet beer, choose a less attenuative strain. For dry, hop-forward styles, select aggressive fermenters that will minimize residual sugars.

Mash Temperature Effects Mash temperature determines the ratio of fermentable to unfermentable sugars in your wort. Lower mash temperatures (148-152°F) favor alpha-amylase enzyme activity, creating more fermentable sugars and higher potential attenuation. Higher temperatures (154-158°F) promote beta-amylase activity, producing more unfermentable dextrins and lower attenuation.

A difference of just 4-6°F in mash temperature can change attenuation by 10-15 percentage points, significantly affecting your beer’s final character.

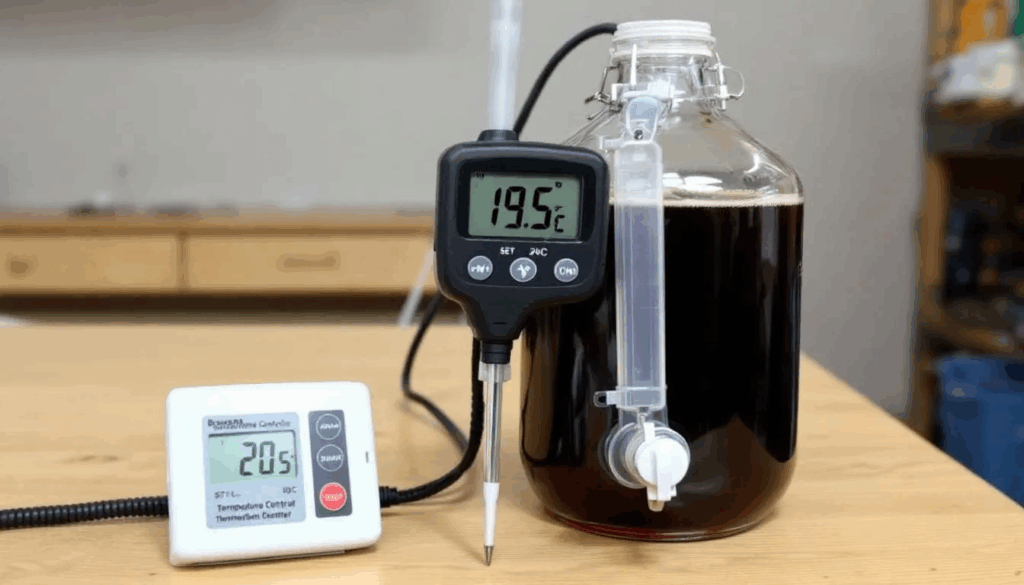

Fermentation Temperature Control Temperature during fermentation affects yeast metabolism and attenuation completeness. Each yeast strain has an optimal temperature range where it performs best. Fermenting too cold may result in stuck fermentation and low attenuation, while excessive heat can stress yeast and create off-flavors despite high attenuation.

Most ale yeasts perform optimally between 64-72°F, while lager yeasts prefer 45-55°F. Maintaining consistent temperatures within these ranges promotes complete attenuation and clean flavor profiles.

Wort Composition and Nutrients Yeast requires proper nutrition for healthy fermentation and complete attenuation. Wort deficient in nitrogen, phosphorus, or trace minerals may result in sluggish fermentation and poor attenuation. All-grain brewers typically have fewer nutrient issues than extract brewers, as malted grains provide natural yeast nutrients.

Consider adding yeast nutrient to high-gravity beers (above 1.065 OG) or recipes with significant adjunct use, as these conditions can stress yeast and reduce attenuation.

Troubleshooting Low or High Attenuation

When your beer attenuation calculator shows results outside expected ranges, identifying and addressing the underlying causes ensures better outcomes in future batches.

Common Causes of Low Attenuation Stuck fermentation leading to low attenuation has several potential causes:

- Insufficient yeast pitch rate: Under-pitching forces existing yeast to work harder, potentially leading to premature flocculation and incomplete attenuation

- Poor yeast viability: Old or improperly stored yeast may lack the vigor needed for complete fermentation

- Temperature issues: Consistent cool temperatures or temperature swings can stress yeast and halt fermentation

- Nutrient deficiency: Particularly common in high-gravity or adjunct-heavy beers

Addressing Low Attenuation If gravity remains high after expected fermentation time:

- Gently rouse yeast by swirling the fermenter

- Raise temperature 2-4°F within yeast tolerance range

- Add fresh, healthy yeast of the same or compatible strain

- Consider yeast nutrient addition if deficiency is suspected

Managing High Attenuation Over-attenuation creates thin, overly dry beer that may lack character. This typically results from:

- Highly attenuative yeast strains

- Low mash temperatures creating excess fermentable sugars

- Wild yeast or bacterial contamination

- Extended fermentation times at elevated temperatures

Prevention Strategies Prevent attenuation issues through proper planning:

- Research yeast specifications and choose appropriate strains

- Control mash temperatures precisely

- Maintain proper fermentation temperatures

- Use adequate pitch rates and healthy yeast

- Monitor fermentation progress with regular gravity checks

When using a beer attenuation calculator for recipe planning, input expected rather than actual final gravity based on your yeast choice and recipe parameters.

Related Brewing Calculations

A beer attenuation calculator often provides additional metrics beyond simple attenuation percentage. Understanding these related calculations helps you predict and control multiple aspects of your finished beer.

Alcohol by Volume (ABV) Calculations Attenuation directly relates to alcohol production, as yeast converts fermentable sugars into roughly equal parts alcohol and carbon dioxide by weight. Most calculators use the formula:

ABV = (OG – FG) × 131.25

This simplified equation works well for beers under 6% ABV. More complex formulas account for alcohol’s non-linear effects on gravity at higher concentrations.

Estimating Final Gravity When recipe planning, you can estimate final gravity using expected attenuation rates:

Estimated FG = OG – ((OG – 1) × Expected Attenuation %)

For example, with OG 1.048 and expecting 75% attenuation: FG = 1.048 – ((1.048 – 1) × 0.75) = 1.012

Calculating Residual Sugars Attenuation data helps estimate remaining fermentable sugars and overall carbohydrate content. Lower attenuation means more residual sugars, contributing to beer body and sweetness. This information proves valuable for diabetic brewers or those monitoring carbohydrate intake.

Beer Calories and Carbohydrate Content Many beer attenuation calculators estimate calories per serving based on alcohol content and residual sugars. The general formula considers:

- Alcohol: 7 calories per gram

- Residual carbohydrates: 4 calories per gram

A typical 12 oz beer with 5% ABV and 75% attenuation contains approximately 150 calories, with roughly 60% from alcohol and 40% from residual sugars.

Using Attenuation for Recipe Development Advanced brewers use attenuation calculations to reverse-engineer recipes. By targeting specific final gravity and alcohol content, you can calculate required original gravity and adjust grain bills accordingly. This approach helps create session beers with desired alcohol levels or balance sweetness in strong ales.

Understanding these interconnected calculations allows you to use your beer attenuation calculator as a comprehensive brewing tool rather than just an attenuation meter. The data helps predict finished beer characteristics and make informed adjustments throughout the brewing process.

Whether you’re troubleshooting fermentation issues, planning new recipes, or simply trying to understand your beer better, attenuation calculators provide essential insights into the fermentation process. By measuring original gravity accurately, monitoring fermentation progress, and calculating final attenuation, you gain the tools needed to brew consistently excellent beer.

Start using a beer attenuation calculator today to take control of your fermentation process and achieve the exact beer characteristics you’re targeting. With practice and attention to the factors affecting attenuation, you’ll develop the skills needed to brew professional-quality beer at home.

Leave a Reply