Accurate sugar content measurement is critical for quality control across brewing, winemaking, and food processing industries. Whether you’re monitoring fermentation progress, ensuring product consistency, or optimizing manufacturing processes, understanding how to properly use a brix calculator can make the difference between success and costly mistakes.

This comprehensive guide will walk you through everything you need to know about brix calculators, from basic measurements to advanced applications across multiple industries. You’ll learn how to convert between different measurement scales, calculate alcohol content, and troubleshoot common measurement errors that may compromise your results.

What is a Brix Calculator and How to Use It

A brix calculator is a tool that measures the percentage of sugar content in liquid solutions, expressed in degrees Brix (°Bx). One degree Brix equals one gram of sucrose in 100 grams of solution, making it an essential measurement for determining sweetness levels and monitoring fermentation processes.

Modern brix calculators come in both digital and analog formats, with most featuring automatic temperature compensation to ensure accurate readings regardless of environmental conditions. The most common type uses refractometer technology, which measures how light bends when passing through your sample.

Step-by-Step Calculator Usage

Using a brix calculator effectively requires proper technique and attention to detail:

- Calibrate your instrument using distilled water at room temperature (should read 0°Bx)

- Clean the sample plate thoroughly with distilled water and dry completely

- Place 2-3 drops of your sample on the measurement surface

- Close the cover plate gently to spread the sample evenly

- Point toward a light source and look through the eyepiece

- Read the measurement where the light and dark boundary intersects the scale

Temperature correction is crucial for accurate results. Most digital refractometers automatically compensate for temperature variations, while manual instruments may require adjustment calculations based on ambient conditions.

The calculator will display your brix reading, which you can then use for further conversions or quality assessments. Starting gravity measurements are particularly important in brewing applications, where initial sugar content determines potential alcohol production.

Brix to Specific Gravity Conversion

Converting brix readings to specific gravity allows brewers and winemakers to use familiar measurement scales and compare results across different measurement methods. Specific gravity measures the density of your solution compared to pure water at the same temperature.

The conversion formula from brix to specific gravity is:

SG = 1 + (Brix × 0.004)

This simplified formula provides accurate results for most brewing and winemaking applications. For more precise conversions, especially in commercial settings, you may need to account for temperature variations and alcohol content.

Conversion Reference Table

Brix (°Bx) | Specific Gravity | Sugar Content |

|---|---|---|

0 | 1.000 | 0% |

5 | 1.020 | 5% |

10 | 1.040 | 10% |

15 | 1.061 | 15% |

20 | 1.083 | 20% |

25 | 1.106 | 25% |

30 | 1.130 | 30% |

Understanding these conversions helps brewers monitor fermentation progress and calculate attenuation rates. When yeast consumes sugar during fermentation, both brix and specific gravity readings will decrease, indicating alcohol production and fermentation completion.

Water content naturally affects these measurements, as dissolved sugar increases solution density above 1.000. This relationship makes gravity readings reliable indicators of sugar concentration and fermentation progress.

Alcohol by Volume (ABV) Calculation from Brix

Calculating alcohol content from brix readings requires both starting and final measurements, as the difference indicates how much sugar was converted to alcohol during fermentation. However, alcohol presence affects refractometer readings, requiring correction factors for accurate results.

The basic ABV calculation formula is:

ABV = (Starting Brix – Final Brix) × 0.59

This formula provides a reasonable estimate for most fermentation scenarios. However, alcohol interferes with refractometer readings because it changes the solution’s refractive index differently than sugar alone.

Alcohol Correction Factors

For more accurate ABV calculations with refractometer readings, use this corrected formula:

Corrected Final Gravity = 1.001843 – 0.002318474×OB – 0.000007775×OB² – 0.000000034×OB³ + 0.00574×CB + 0.00003344×CB² + 0.000000086×CB³

Where OB is original brix and CB is current brix reading.

Example calculation: If your initial reading was 25°Bx and final reading is 8°Bx after fermentation, your estimated ABV would be approximately 10%. However, applying alcohol correction factors may adjust this figure by 0.5-1% depending on fermentation characteristics.

These calculations become particularly important in commercial brewing operations where precise alcohol content affects taxation, labeling requirements, and quality control standards. Many professional brewers use specialized software or advanced calculators that automatically apply these correction factors.

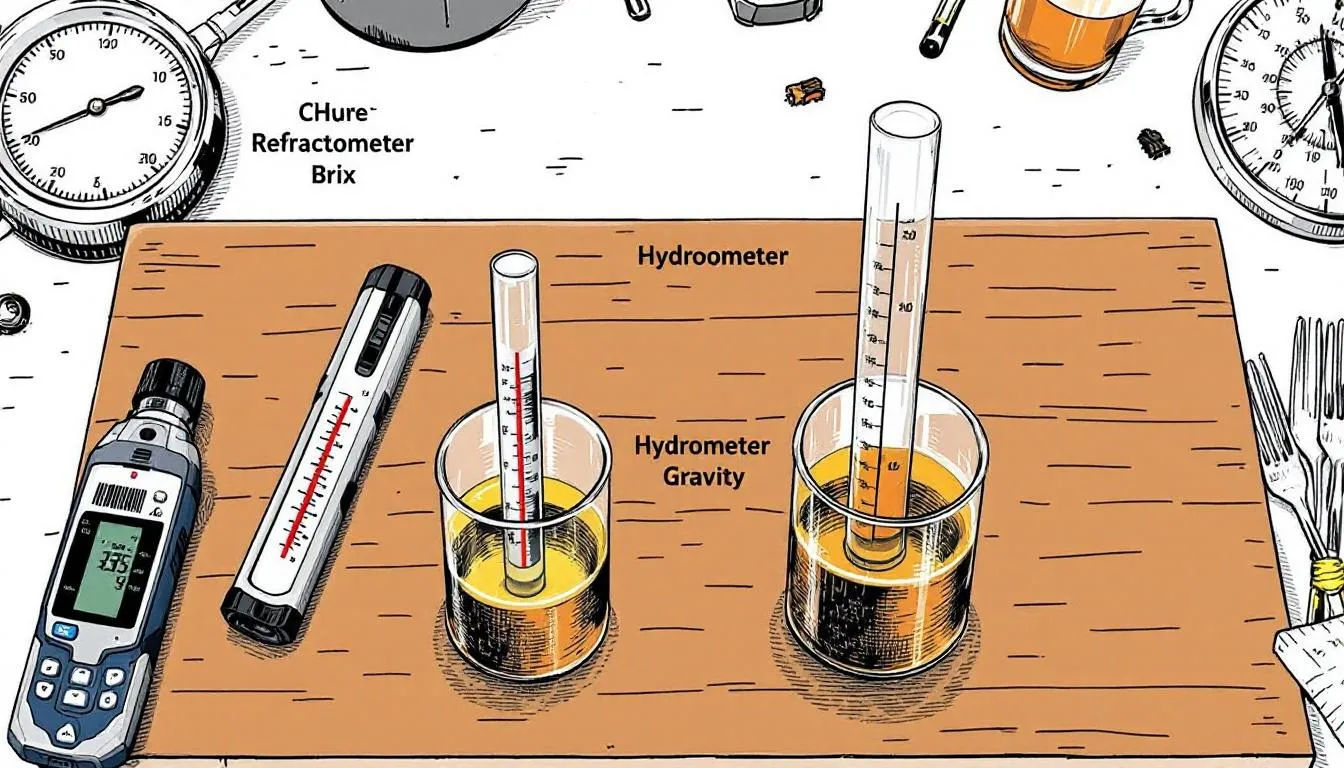

Brix Measurement Tools and Equipment

Selecting the right measurement equipment depends on your accuracy requirements, budget, and application frequency. Refractometers offer superior precision and convenience compared to traditional hydrometers, requiring only small sample volumes and providing instant readings.

Digital refractometers represent the current industry standard for professional applications. These instruments automatically compensate for temperature variations and often include multiple measurement scales beyond just brix. Advanced models may store readings, calculate averages, and connect to computer systems for data logging.

Optical refractometers remain popular for smaller operations and field measurements. While requiring manual reading interpretation, they’re generally more affordable and don’t require batteries or electronic components that may fail in harsh environments.

Temperature Compensation Features

Modern refractometers include automatic temperature compensation (ATC) that adjusts readings to standard reference temperatures. This feature is essential because refractive index changes significantly with temperature – approximately 0.00045 per degree Celsius for sugar solutions.

Manual temperature compensation requires converting readings using correction tables or formulas. For every degree above 20°C (68°F), subtract 0.0007 from your brix reading. For temperatures below 20°C, add the same correction factor.

Calibration procedures should be performed regularly using distilled water at 59°F (15°C). Place several drops of distilled water on the measurement surface and adjust the instrument to read exactly 0.00°Bx. Some instruments include calibration solutions for additional verification points.

Refractometer Reading Accuracy

Refractometer readings typically provide accuracy within ±0.1°Bx when properly calibrated and used correctly. This precision surpasses hydrometer measurements, which may vary by ±0.002 specific gravity units due to temperature effects and reading interpretation errors.

Sample preparation affects measurement accuracy significantly. Ensure samples are well-mixed and representative of the entire batch. Avoid samples with suspended particles or foam, which can interfere with light transmission and create reading errors.

Environmental factors like ambient light intensity and temperature stability also influence measurement precision. Use consistent lighting conditions and allow instruments to acclimate to room temperature before taking readings.

Common reading errors include:

- Insufficient sample volume creating air bubbles

- Contamination from previous samples

- Improper calibration or calibration drift

- Temperature compensation failures

Applications of Brix Calculators

Brix calculators serve diverse industries where sugar content monitoring is critical for quality control, process optimization, and regulatory compliance. Each application has specific requirements for accuracy, measurement frequency, and documentation.

Food processing operations use brix measurements to standardize product sweetness and monitor concentration processes. Fruit juice manufacturers and wine producers both rely on brix calculators as essential tools. Fruit juice manufacturers target specific brix ranges—typically 8-20°Bx for products like orange juice—to ensure consistent flavor profiles and meet labeling requirements. In the wine industry, brix calculators are used to monitor the sugar content of grape juice and must, track fermentation progress, and control the production process to achieve the desired alcohol level and product quality.

In vegetable processing, particularly potato preparation for fries and chips, lower brix values are preferred. Potatoes with readings above 5°Bx tend to brown excessively during cooking and may develop poor texture characteristics.

Dairy industry applications focus on colostrum quality assessment for newborn animals. Higher brix percentages indicate superior immunoglobulin content, making this measurement critical for livestock health management.

In brewing, brix calculators are used in beer production to monitor fermentation, process control, and consistency throughout each batch. Brewers use these instruments to test wort and beer samples, track sugar conversion by yeast, and ensure the final product meets quality standards.

Brewing Industry Applications

Brewing operations rely heavily on brix measurements for recipe formulation, fermentation monitoring, and quality control. Original gravity determination helps brewers calculate ingredient quantities and predict final alcohol content.

During fermentation, regular brix readings track yeast activity and sugar consumption rates. Stalled fermentations often show stable readings over multiple days, indicating the need for intervention or nutrient additions.

Attenuation calculation compares starting and final gravity to determine fermentation efficiency. Well-attenuated beers typically reach 75-85% apparent attenuation, while under-attenuated batches may indicate yeast health issues or environmental problems.

Commercial brewing operations integrate brix measurements into automated quality control systems. Continuous monitoring allows real-time process adjustments and helps maintain product consistency across multiple production runs.

Manufacturing applications extend beyond food and beverage industries. Metalworking fluid concentration monitoring uses brix readings as a proxy for cutting oil potency and dilution ratios. Proper concentration levels ensure adequate lubrication while minimizing bacterial growth and tool wear.

Brix, Plato, and Balling Scale Relationships

Understanding the relationships between different sugar measurement scales helps when working across industries or comparing historical data. Brix, Plato, and Balling scales are essentially interchangeable for most practical purposes, with minor differences in their original calibration methods. A typical conversion table is often used to show the relationship between Brix, Plato, and Balling scales.

The Plato scale, primarily used in European brewing, measures extract content by weight percentage. Modern Plato measurements are virtually identical to Brix readings, with differences typically less than 0.1% at normal brewing concentrations.

Balling scale preceded both Brix and Plato, developed in the 19th century for brewing applications. While historically significant, Balling is rarely used in modern applications, having been superseded by more accurate calibration methods.

Conversion Formulas and Standards

For practical purposes, these scales can be considered equivalent:

- 1° Brix ≈ 1° Plato ≈ 1° Balling

Precise conversions require temperature and alcohol content considerations:

- Brix to Plato: Plato = Brix × 1.004

- Plato to Brix: Brix = Plato × 0.996

Industry standards vary by region and tradition. German and Czech breweries often prefer Plato measurements, while American operations typically use Brix or specific gravity. Wine industries worldwide have largely standardized on Brix measurements.

Historical development of these scales reflects improvements in measurement accuracy and standardization efforts. Modern instruments typically offer multiple scale options, allowing users to select their preferred measurement system while maintaining underlying accuracy.

Regional preferences persist despite scale similarities. Understanding these preferences helps when interpreting recipes, technical literature, or collaborating with international partners. Most conversion software and advanced calculators support multiple scales simultaneously.

Common Brix Calculator Errors and Troubleshooting

Measurement errors can significantly impact product quality and process control decisions. Understanding common problems and their solutions helps maintain accuracy and reliability in your brix measurements. When troubleshooting, review your measurement data to identify patterns or recurring errors that may indicate underlying issues.

Temperature correction mistakes represent the most frequent source of error in brix calculations. Many operators forget to account for sample temperature differences or incorrectly apply compensation factors. Always verify that your instrument’s temperature compensation is functioning properly and calibrated correctly.

Alcohol interference affects refractometer readings in fermented samples, causing artificially high brix values. This occurs because alcohol has a different refractive index than water, skewing the sugar content calculation. Use alcohol correction formulas or specialized brewing refractometers designed to compensate for this interference.

Calibration and Maintenance Issues

Calibration drift occurs gradually as instruments age or experience environmental stress. Regular calibration checks using distilled water and certified reference solutions help identify drift before it affects measurement accuracy.

Sample contamination from previous measurements or environmental sources can cause significant errors. Clean measurement surfaces thoroughly between samples and verify that cleaning solutions are completely removed before taking readings.

Common troubleshooting steps include:

- Verify calibration using multiple reference points

- Check temperature compensation functionality

- Inspect optical surfaces for scratches or contamination

- Confirm sample preparation procedures

- Review environmental conditions during measurement

Maintenance schedules should include daily cleaning, weekly calibration verification, and periodic professional servicing. Document all calibration and maintenance activities to track instrument performance over time.

Advanced troubleshooting may require technical support or instrument replacement. Symptoms like unstable readings, inability to calibrate, or visible optical damage typically indicate the need for professional repair or replacement.

Sample-related errors often stem from improper preparation or handling. Ensure samples are representative, well-mixed, and free from suspended particles that may interfere with optical measurements. Store samples at appropriate temperatures and measure promptly to avoid degradation or fermentation changes.

Environmental factors like vibration, extreme temperatures, or poor lighting can affect measurement accuracy. Establish consistent measurement conditions and protect instruments from environmental extremes during storage and operation.

Regular training for operators helps prevent human errors and ensures consistent measurement techniques. Document standard operating procedures and provide periodic refresher training to maintain measurement quality across your organization.

Understanding the limitations of your measurement system helps set realistic expectations and identify when additional verification methods may be necessary. Complex samples or critical applications may require multiple measurement techniques or laboratory confirmation of results.

Proper documentation of measurements, calibrations, and maintenance activities supports quality management systems and regulatory compliance. Many industries require detailed records of measurement procedures and accuracy verification for audit purposes.

By following these guidelines and maintaining awareness of potential error sources, you can maximize the accuracy and reliability of your brix measurements while supporting consistent product quality and process control across your operations.

Leave a Reply